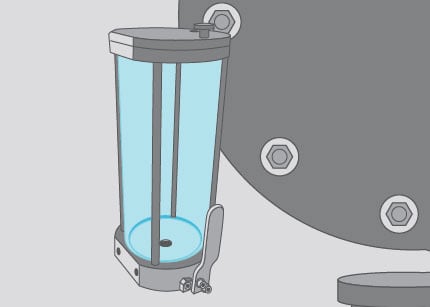

A fuel water detector can be used in jet fuel to find out if there is any water that cannot be seen with the naked eye.

In the case of the Shell Water Detector, it’s a capsule that you attach to a syringe, which you use to draw out 5ml of jet fuel. When testing jet fuel with the Shell Water Detector, watch to see if it changes colour from yellow to blue; this means that there is water.

Using a fuel water detector will help you find out if water has got into your fuel and allow you to deal with it before it becomes a problem for your aircraft.

Free water in aviation fuel can lead to ice formation, filter blockages and consequent engine failure. It can also allow microbial growth in fuel tanks, which can cause fuel spoiling and filter blocking. Acids generated by the microbes can even cause corrosion damage.

Low concentrations of water suspended in fuel cannot be detected by visual inspections.

Developed by Shell to address aircraft operational issues associated with ice formation in aircraft fuel tanks, Shell Water Detector is an easy-to-use, reliable and simple industry-standard test method that verifies that jet fuel meets the demanding aviation standards for water content.

It detects the presence in jet fuels of finely dispersed water that is undetectable by the eye and gives assurance to the user that the industry limits for water-free jet fuel are maintained.

Shell water detectors also feature flip-tops, making them easy to open with one hand while wearing gloves.

When to use fuel water detectors

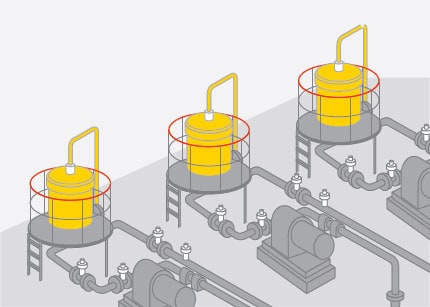

Water can get into your jet fuel at every stage of the supply chain. The Joint Inspection Group (JIG), which sets the standards for aviation fuel supply, requires you to test your jet fuel at every stage.

Use fuel water detectors daily to test the fuel stored in in-service tanks, hydrant filter drains, loading filter drains, fueller filter drains, hydrant dispensers, fueller tanks and trailer tanks.

Since water can enter your fuel supply chain in multiple locations, JIG stipulates that you should test in accordance to the following:

For more information, please visit https://www.asearle.co.uk/shell-water-detector.